litho printing vs Inkjet Printing: What to Know

A Comprehensive Overview to Comprehending Litho Printing Methods

The globe of litho printing, a technique stemming from the late 18th century, is a remarkable mix of history, advancement, art and scientific research. This comprehensive guide will certainly decipher the complexities of this printing approach, from the composition of litho inks to the challenges faced in modern-day applications. As we venture into the intricacies of lithography, the importance of automation and sustainability in ensuring its future relevance comes to be significantly clear. Stick with us as we trip right into the exciting world of litho printing.

The Historical Development of Litho Printing

The historical trajectory of litho printing, a crucial advancement in the world of interaction, is a captivating story of human ingenuity. Birthed in the late 18th century by Alois Senefelder, this strategy was initially a cost-effective approach of releasing theatrical jobs. Lithography, originated from the Greek words for 'rock' and 'to write', utilized a smooth rock surface to move pictures onto paper. The procedure advanced with the arrival of the rotary press, which substantially raised performance (litho printing). In the 20th century, the innovation of balanced out lithography changed the industry, allowing for mass production of high-grade prints. Each stage of litho printing's development showcases humankind's ruthless quest of performance and top quality in visual communication.

Translating the Science Behind Litho Printing Inks

Moving on in the expedition of litho printing strategies, the emphasis currently moves to the science behind litho printing inks. The structure of these inks, their drying out process, and color mixing techniques form the foundation of this complex art kind. Comprehending these components is vital to mastering the craft and attaining the preferred print results.

Composition of Litho Inks

In lithographic printing, the fundamental role of litho inks can not be overstated. The structure of litho inks differs depending upon its purpose, however normally, they are composed of 2 main components - pigments and vehicles. Pigments, the color-providing components, are finely ground bits suspended in the automobile, a fluid that carries the pigment onto the printing surface area. The car is a complicated combination of materials, oils, and solvents, which influence the ink's drying time, adhesion, and gloss. Furthermore, various additives are existing to enhance particular homes like flow, drying out, and resistance to environmental effects. Each part plays a critical part in the last print's quality, making the exact formulation of litho inks an elaborate scientific research.

Ink Drying Refine

From the composition of litho inks, attention transforms to the interesting process of ink drying out. 2 primary methods are utilized in litho printing: oxidative drying and absorption. Absorption, on the other hand, involves the ink seeping into the paper fibers, which is a quicker process but can lead to less vibrant shades.

Shade Mixing Methods

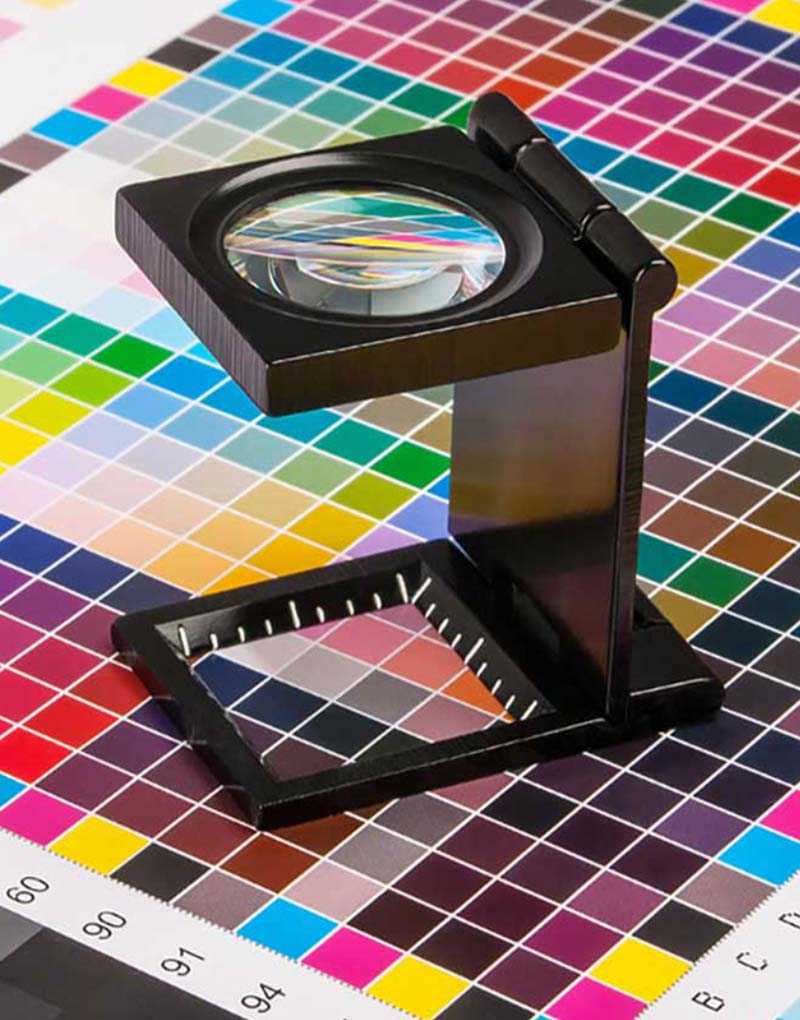

While the drying out procedure plays a key duty in litho printing, the scientific research of shade blending methods holds equivalent significance. This is a complex process that includes the cautious blending of primaries: cyan, magenta, and yellow, in varying percentages to attain a wide array of colors. The addition of black ink, recognized as 'crucial', helps in regulating the strength and depth of the shades. The science behind litho printing inks also considers the transparency of the ink, which impacts how shades overlay and mix. To accomplish a reliable color mix, print specialists have to also comprehend the ins and outs of ink habits, shade concept, and the physical properties of the substratum on which the ink is applied.

The Art and Design Aspects in Litho Printing

Litho printing takes a breath life right into art and layout through its distinct components. The process includes producing an image on a lithographic sedimentary rock plate or steel plate with a smooth surface area. The image is then published onto a medium, generally paper, by moving the ink from the plate. What collections litho printing apart is its capacity to replicate complex styles with high integrity, making the result practically similar to the initial artwork. This is accomplished with making use of various line methods such as hatching, cross-hatching, and stippling, which enable a variety of tonal results. In addition, litho printing accommodates a variety of shades, enabling musicians to develop dynamic and vibrant prints. This mix of precision and flexibility makes litho printing a recommended option for lots of musicians and designers.

Modern Applications of Litho Printing Methods

Litho printing techniques have my company found extensive use in the modern industrial sector. Its influence and importance remain to expand with the introduction of brand-new advancements and innovations in the field. This section will certainly explore these contemporary applications and the transformative function they play in the printing market.

Business Litho Printing Makes Use Of

Litho printing stays a critical component of the industrial sector. High-volume printing tasks, such as the production of books, newspapers, and packaging, depend on litho printing for its capacity to deliver superior photo high quality and cost performance. Litho printing likewise provides a wide color spectrum, remarkable to that of digital printing.

Advancements in Litho Printing

Pushing the boundaries of traditional methods, contemporary improvements have actually sustained a host of advancements in litho printing. One popular advancement is digital litho printing, which integrates the merits of electronic innovation with litho's high-quality outcome. These technologies emphasize the enduring significance of litho printing in the contemporary world.

Discovering the Process of Litho Printing: Action by Action

Obstacles and Solutions in Contemporary Litho Printing

In spite of the precision and practice that litho printing proudly promotes, it is not without its collection of contemporary obstacles. Digital litho printing permits for economical short runs and simple personalization, dealing with the problem of variable data. Thus, while there are obstacles, the litho printing market is proactively adjusting to fulfill them head-on, guaranteeing its significance in the future.

Final thought

Finally, litho printing, with its abundant background and scientific ins and outs, holds a considerable place in the print sector. As the overview discloses, it's a synthesis of art and technology, with modern-day advancements ensuring its relevance. The market faces obstacles that need cutting-edge remedies, with an emphasis on automation and sustainability. The future of litho printing pivots on its ability to adapt to these transforming demands, verifying its enduring worth in a progressing market.